Just How to Make Certain Long Life and Dependability with a High-Quality Membrane Switch

Exactly How Membrane Layer Switches Contribute to the Sturdiness of Electronic Control Panels

Membrane buttons play a vital function in enhancing the durability of electronic control panels, largely via their multi-layered building which offers reliable security against ecological aspects such as dampness and dirt. The absence of relocating components substantially minimizes the likelihood of mechanical failures, making membrane switches over suitable for demanding applications.

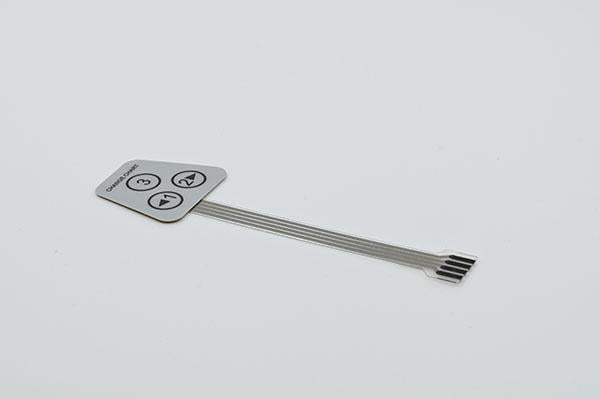

Meaning of Membrane Layer Buttons

Membrane switches are created to be thin and light-weight, making them suitable for applications where room is restricted. They can be produced in various forms, dimensions, and colors, supplying versatility in layout that meets visual and practical requirements. Furthermore, membrane switches can integrate various innovations, such as responsive comments and LED indicators, improving user experience.

Due to their construction, membrane switches are commonly immune to dirt, wetness, and basic wear, adding to their resilience in demanding atmospheres. Their smooth layout not only assists in very easy cleaning but also reduces the threat of mechanical failing, making them a preferred choice for makers looking for reliable user interfaces in their digital control board.

Defense Against Ecological Factors

The design of membrane layer switches inherently gives a level of security against various environmental elements, which is crucial for keeping functionality in challenging problems - Membrane Switch. These switches are typically constructed with layers of adaptable materials that shield inner components from wetness, dirt, and pollutants. By enveloping the circuitry, membrane layer switches over decrease the risk of brief circuits and rust, which can substantially impair efficiency

Additionally, making use of durable adhesives and sealers during manufacturing improves their resistance to environmental obstacles. Membrane buttons can sustain exposure to chemicals and solvents, making them ideal for industries such as food processing and health care, where health and cleanliness are paramount. Their seamless surface area design also protects against the build-up of dust and bacteria, promoting less complicated cleaning and upkeep.

Temperature level changes are an additional ecological worry, and membrane buttons are crafted to function properly across a wide variety of temperature levels (Membrane Switch). This adaptability makes sure that control board remain operational in various settings, from industrial atmospheres to customer electronics

Effect On Individual Interaction

User communication with digital control panels is dramatically influenced by the style and capability of membrane switches. These switches offer a tactile user interface that boosts the overall individual experience, enabling instinctive navigating and control. Their Full Report responsive nature ensures that users get instant comments upon activation, which is critical for jobs requiring precision and efficiency.

Furthermore, the smooth surface of membrane changes promotes easy cleaning and maintenance, promoting individual confidence in the reliability of the interface. This tidiness is particularly vital in atmospheres where hygiene is vital, such as medical or food processing setups. Additionally, the compact and lightweight style of membrane switches adds to the visual appeal of control board, urging customer involvement with a contemporary and streamlined look.

Furthermore, the assimilation of visual components, such as published icons and backlighting, helps users swiftly determine features, lowering the discovering curve related to brand-new equipment. Therefore, customers can operate tools better, bring about raised efficiency and complete satisfaction. In recap, membrane buttons play an essential role in boosting individual interaction by combining capability, aesthetics, and convenience of use, inevitably causing improved functional effectiveness.

Design Versatility and Customization

Layout flexibility and modification are necessary aspects of membrane layer switches, allowing manufacturers to customize electronic control board to particular applications and customer needs. This flexibility permits the integration of various style components, such as colors, graphics, and appearances, which can enhance the visual appeal and customer engagement of the control board.

Membrane layer switches can be personalized in shapes and size, suiting a broad variety of tools and applications, from industrial machinery to customer electronic devices. This adaptability ensures that producers can develop instinctive interfaces that align with customer assumptions and operational needs. In addition, the ability to incorporate distinct features such as backlighting or tactile comments additionally boosts usability, permitting for a more interactive experience.

Additionally, the manufacturing procedure for membrane layer switches over sustains the fast prototyping of designs, enabling producers to iterate and fine-tune their ideas swiftly. This capacity not just increases the development timeline yet additionally ensures that the end product fulfills details useful and visual criteria.

Cost-Effectiveness and Durability

Cost-effectiveness and durability why not check here are considerable advantages of membrane buttons, making them an attractive choice for makers and end-users alike. These switches are usually much less pricey to create than conventional mechanical switches, primarily as a result see it here of their streamlined manufacturing processes and the lowered variety of parts needed. This cost benefit prolongs not only to first manufacturing however likewise to long-term functional costs, as membrane layer buttons typically need less upkeep and have a lower failure price.

Furthermore, the long life of membrane layer changes adds to their total value. Created from resilient materials, they are resistant to environmental aspects such as wetness, dirt, and chemicals, which can cause premature wear in various other switch kinds. The absence of relocating parts decreases mechanical failure, permitting membrane changes to keep performance over expanded periods.

This toughness is particularly valuable in applications needing consistent performance under requiring conditions, such as clinical devices and industrial tools. Ultimately, the mix of cost-effectiveness and longevity makes membrane switches over an economically feasible choice for makers, offering reputable remedies that stand up to the test of time while optimizing monetary factors to consider.

Conclusion

Finally, membrane switches dramatically boost the toughness of digital control board through their robust building and construction and protective functions. By effectively shielding circuitry from environmental dangers and decreasing the threat of mechanical failure, these switches make sure constant efficiency sought after applications. The smooth layout advertises hygiene and ease of maintenance, while customization options allow tailored services for different requirements. Generally, membrane layer changes stand for a trusted and cost-effective option for enhancing the durability and performance of electronic control systems.